Corrosion, broken springs, and unstable operating conditions: A centrifugal pump has repeatedly failed at a chemical production facility at DOW Chemical. It was only the targeted use of sensors on the mechanical seal and structured data analysis that finally brought clarity – and ensured that the pump and production were running stably again.

Seals are often considered inconspicuous components – but in process-critical applications, they are decisive for downtime or smooth operation. This was also the case at DOW Chemical in Böhlen, Germany, where a centrifugal pump was used at high temperatures and in contact with aggressive sulfuric acid. Problems arose time and again in the supply system of the seal:cracked oil, traces of corrosion, damaged seal components. The consequences were uncertainties in operation, unclear causes and high repair costs.

Tracking down the causes

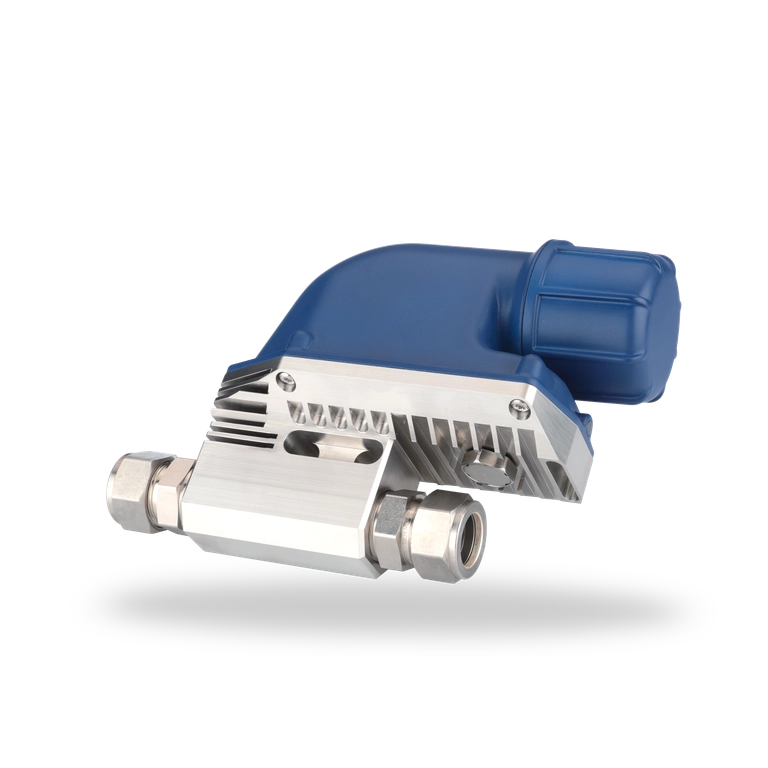

Together with the customer, EagleBurgmann started a structured root cause analysis. The first step: retrofitting the system with EB Smart Seal® Sensors to monitor temperature, pressure, flow rate and other operating parameters – directly at the seal inlet and outlet. The recorded data was transmitted wirelessly to an IoT gateway and stored in the myEagleBurgmann Cloud. There, experts from EagleBurgmann continuously analyzed the values as part of the Smart Condition Monitoring service. “We wanted to under stand what exactly happens in the pump – not just make assumptions,” explains Christian Ihrke, Head of Service Center Halle/Leipzig at EagleBurgmann. Although measured values from the customer‘s process control system were already available, these were not sufficient to explain the behavior of the machine in detail. It was only the digital condition monitoring system that brought the necessary transparency.

From suspicion to solution

It soon became apparent that the circulation pump in the supply system of the seal was defective, and the barrier fluid was stagnating. The heat dissipation no longer worked – with serious consequences for the seal. The

system reacted as intended. It triggered alerts that were delivered in real-time to the customer and EagleBurgmann teams.Targeted measures followed: the barrier pressure was adjusted, defective components were replaced, and improvements in terms of circulation and temperature control developed. The sensor technology even revealed a faulty screw connection, which further hindered the flow. After replacing the circulation pump, the temperatures stabilized – the pump and production were running normally for the first time in a long time. “The collaboration with EagleBurgmannwas a real turning point for us,” confirms Bernhard Fröhlich, PPM Technologist Leader Maintenance at DOW Chemical. “For the first time, we really understood what happened in the seal and were able to take targeted countermeasures instead of trying out expensive assumptions.”However, there is more to quick problem solving than just troubleshooting. The goal for EagleBurgmann is to develop a better understanding of the condition of the respective seal and its supply on the basis of operating data. In this way, technical relationships can be understood, and well-founded decisions can be made during operation. “With the combination of sensors and data analysis, we can avoid damage and also provide our customers with concrete recommendations for efficient and safe operation,” explains Dr. Max Botz, Development Engineer IoT Sensors at EagleBurgmann. “This is exactly the core of our Smart Condition Monitoring service."

Want to benefit from the advantages of the Smart Condition Monitoring System?

Contact us