Case Study

The value of using the Smart Condition Monitoring System by EagleBurgmann is demonstrated by the case of long-time EagleBurgmann customer, Leuna Carboxylation Plant GmbH (LCP). EB Smart Seal Sensors were installed on a paddle dryer in 2022. „Our goal was to protect the high-quality component of this process-critical system and to guarantee safe operation for as long as possible,“ explains Robert Tulaszewski, Operations Engineer at LCP.

LOCATION: Leuna, Germany

INDUSTRY: Chemical Industry

Challenge

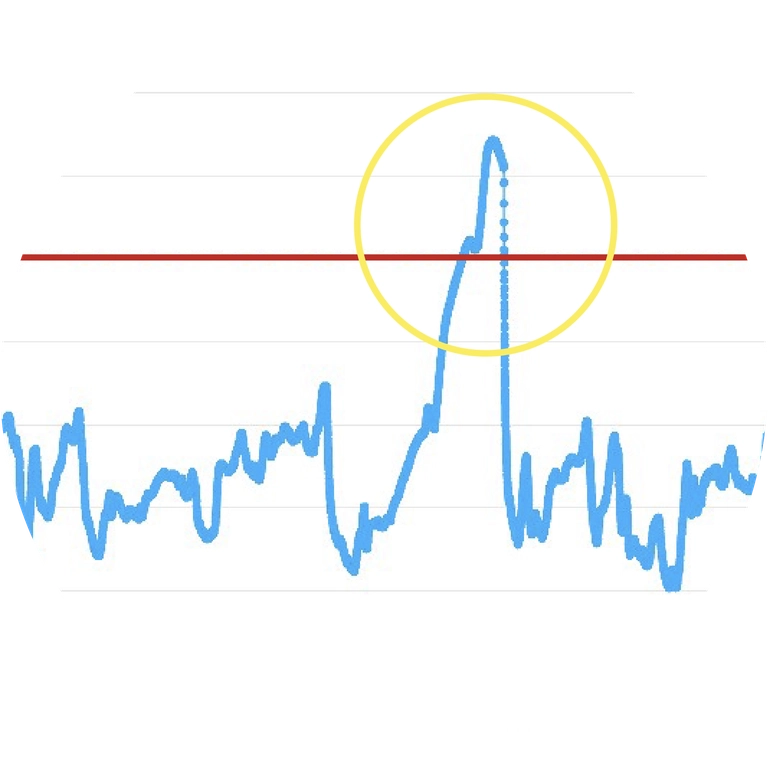

The temperature in the dryer‘s supply system suddenly rose to unusually high levels, which leads to seal damage or even seal failures with production downtime.

Solution

If a parameter exceeds a predefined limit, an alarm is triggered, and the customer is notified. Smart Condition Monitoring detected the temperature rise early. An alarm was triggered and LCP and EagleBurgmann experts were notified of the sudden temperature rise in the system. LCP found the problem in the cooling system, fixed the issue and major damage was prevented.

Want to benefit from the advantages of the Smart Condition Monitoring System?

Contact us